Data

Network Infrastructure

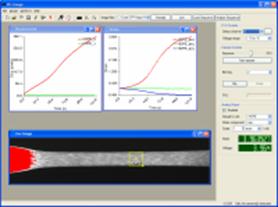

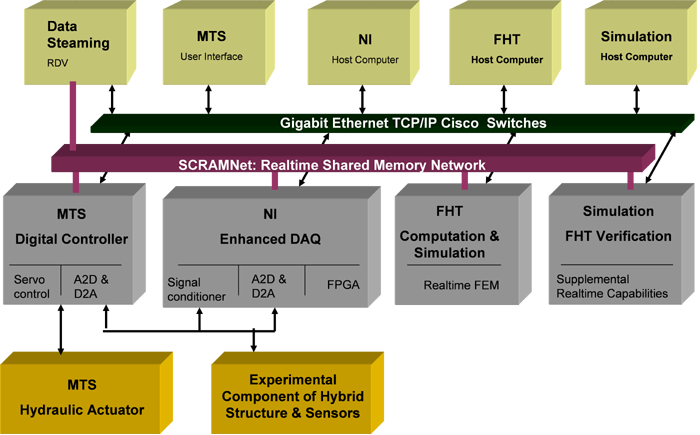

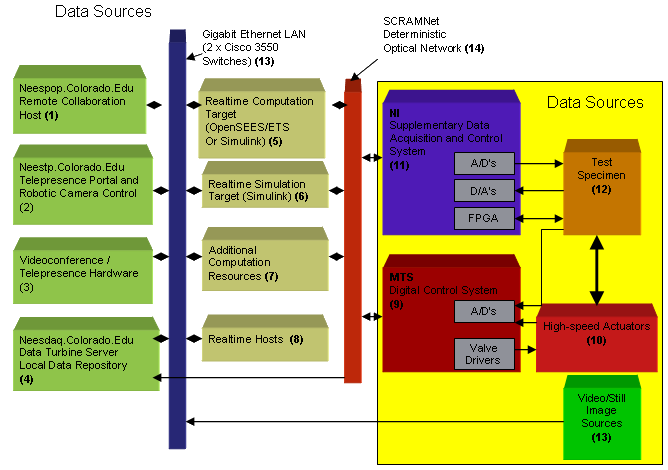

The CU-FHT site operates a network of computers to perform the multiple tasks involved before, during, and after a hybrid simulation.

The coordination of these machines is done by two networks: a gigabit-Ethernet network for data sharing and bulk data transfer, and a SCRAMNet for realtime communication.

The bulk of user interaction is done via several host computers. On these host computers the user can configure various parameters of the hybrid test, such as modeling the structure to be analyzed, select data quantities to capture, and which actuators to activate during a simulation. This configuration is performed before the hybrid simulation, and files needed for configuration such as ground motions, material parameters, and others are transferred using the Ethernet network. Similarly, after a hybrid simulation the collected data is stored in a local repository and possibly sent to a remote site for storage and/or visulaization again using the Ethernet network. However, while the Ethernet network is used extensively both before and after a hybrid test, the SCRAMNet network is use primarily during a hybrid test.

During a fast hybrid simulation, there are multiple computer platforms running simultaneously, each performing a different task associated with the simulation. One computer (running a real time operating system) will be performing the numeric simulation of the structure, while another will communicate with and control the physical test equipment, and a third computer might be storing data generated by the test. All these computers need to communicate with each other during the simulation in a near instantaneous fashion.

While the standard Ethernet-based network would work for a pseudodynamic hybrid test, Ethernet as a network protocol is unsuitable for fast and realtime hybrid simulations due to the nondeterminism of the Ethernet network. Specifically, Ethernet is an example of a "best-effort" network; if computer A tries to send data to computer B over Ethernet, there is no upper limit to the transmittal time. When results have to be analyzed and produced 1,024 times a second, the unpredictability of Ethernet is a serious liability for fast and realtime hybrid tests. To this end, a network which has guaranteed delivery time as one of its characteristics is adopted. The SCRAMNet network is a deterministic data network that appears as distributed shared memory to all the computers using it. When a computer on the SCRAMNet writes data to a particular memory location in the SCRAMNet memory space, that data appears on the memory space of all the other computers, connected to the SCRAMNet. This effect is deterministic; the data transfer is guaranteed to occur within a specified time, on the order of nano- or micro-seconds. The end result is that data results provided by the simulation computer are guaranteed to be sent to the actuator controller in a timely manner. Using a different network -- such as Ethernet -- it would be possible that data could be delayed or dropped altogether, such that the actuator controller will not have any new data for the next 0.97-millisecond update.

The numeric computation portion of a fast hybrid test runs on the primary realtime host, which is a standard PC with a realtime operating system (Phar-Lap ETS) and simulation software.

This PC is connected via SCRAMNet to the actuator controller and the data collection platform. Although the computation software currently used is a heavily customized version of OpenSees, any simulation software could be used if properly modified to run on the realtime operating system.

Various other tasks related to a hybrid test can be performed on the secondary realtime host, which is also a standard PC with a realtime operating system and SCRAMNet hardware. The secondary realtime host serves as a backup of the primary realtime host, but can perform other tasks as well, such as simulating the response of actual test hardware or processing data as it flows through the SCRAMNet network.

Data is gathered by three separate platforms, for different purposes. The first platform is the management computer directly connected to the MTS controller. This management PC allows the viewing and saving of various control quantities for diagnostic purposes. For instance, all the data being measured by instruments in the MTS controller are available to the management computer.

In addition, the MTS controller writes all of its control and measurement quantities to specific memory locations in the SCRAMNet memory space, so that other computers on the SCRAMNet can view, process, and possibly record these values. The second platform, a data streaming computer platform, reads all these data values from the SCRAMNet and pushes them onto the CU-FHT data turbine, which allows for remote viewing of the data quantities using RDV. This is used to view realtime, streaming data over the network for a data turbine server, synchronizes numeric, video and still images, and allows for instant replay with variable speed playback.

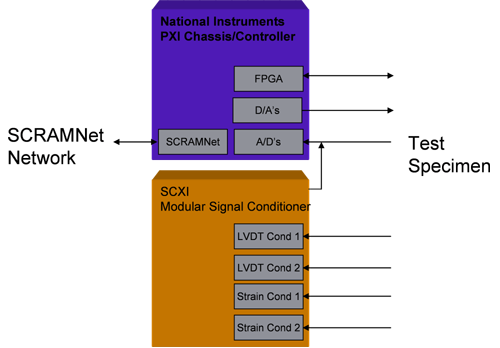

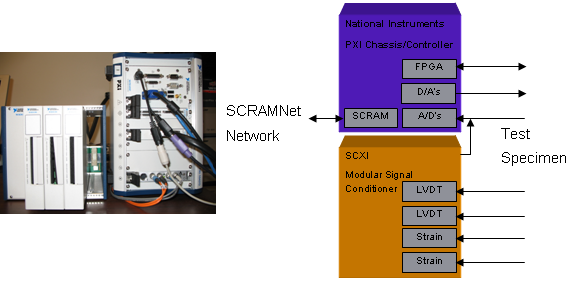

The third platform is a National Instruments PXI chassis containing a PC, SCRAMNet hardware, and a panoply of other instrumentation I/O, for (locally written) Hybrid Data Acquisition (DAQ) system. It plays a key role in the Fast Hybrid Testing (FHT) system by acquiring time synchronized data from test specimen mounted physical sensors and node/element data from within the numerical model in real time.

Physical sensor data is acquired using conventional National Instruments multi-function I/O hardware and SCXI signal conditioning hardware, while numerical model data is acquired using a SCRAMNet network interface card. The SCRAMNet network is the communication backbone of the FHT system. All feedback and command signals are exchanged at a rate of 1024 Hz across the SCRAMNet. Using a LabVIEW Realtime program, the Hybrid DAQ acquires a preprogrammed list of SCRAMNet channels using the MTS generated network interrupt as a clock signal. The system can acquire over 500 channels at 1024 Hz. in its current configuration. All acquired data is written to a Matlab format file or a tab delimited text file.

Data Sources

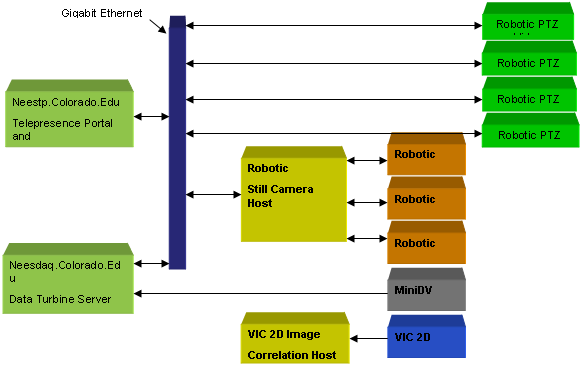

These items describe the below depiction of devices attached to our network:NEESGrid Infrastructure (Items 1-4)

- NEES Point of Presence (NEESPOP). Hosts online collaborative environment, scheduling system, project resources, etc.

- NEES Telepresence Server (NEESTP). Hosts streaming video feeds, routes robotic camera control commands to our four robotic telepresence cameras.

- Video Conference and Telepresence Hardware. Consist of a Polycom Viewstation H.323 compatible video conference unit and four Axis 2401 streaming video servers.

- NEES Data Acquisition Server. Acquires realtime data from SCRAMNet and publishes it to Data Turbine where it is available for viewing by remote users. The server also host our local data/file repository.

FHT Computational Components (Items 5-8)

- Realtime Computation Target. The computer runs the finite element model of the structure with which the test specimen in is interacting. The timing constraints of Fast-Hybrid testing require the finite element modeling program, OpenSees, to run in the hard realtime operating system ETS.

- Realtime Simulation Target. This machine is used to simulate the physical actuators and test specimen while new structural models and specimens are being developed. Simulating the test prior to real testing provides an opportunity to understand and anticipate the conditions and events which will take place during a real test.

- Additional Computational Resources. These resources represent parallel computing platforms that may be local or remote. The computational resources work in tandem, or in place of the realtime computation target.

- Realtime Hosts. The realtime hosts provide the user interface and development environment for the realtime target systems.

MTS Servo Hydraulic System (Items 9-10)

- MTS Digital Controller. The MTS controller controls three high performance hydraulic actuators. It is responsible for reading displacement or force commands from the SCRAMNet, measuring actuator feedback, and generating the appropriate servo valve command to drive each actuator to the commanded point. In addition the controller serves as a 48-channel data acquisition system for specimen mounted instrumentation (accelerometers, LVDTs, strain gages, etc)

- High-performance Actuators (3). Two 100-Kip, 20-in/sec actuators and 1 220-kip 12-in/sec actuator with force, displacement, and delta p feedback.

Supplementary Data Acquisition System (Item 11)

- This embedded Realtime or Windows based system contains additional data acquisition and control hardware. Data from SCRAMNet can be used to control specimen behavior, such as damping force. The system can also acquire up to 1000 channels of data from the SCRAMNet and record it in realtime. The system contains a software programmable "hardware-in-the-loop" Field Programmable Gate Array which can be utilized for special testing and simulation needs.

Test Specimen (Item 12)

- Test Specimen.

Network Components (Items 13-14)

- Cisco Gigabit LAN. Our local area network consists of both private and public subnets. Each subnet utilizes a Cisco Catalyst 3550 gigabit copper Ethernet switch.

- SCRAMNet Optical Network. SCRAMNet is a reflective memory network. Each host on the network has a 2-megabyte section of mapped RAM. Data written to this special RAM area is mirrored with sub-microsecond latency to each host on the network. The low latency and event driven network interrupt architecture of SCRAMNet is a central component in the FHT system.

The CU FHT equipment network is a flexible and scaleable system which can be easily adapted to incorporate additional physical testing equipment and computational resources as demanded by individual tests. The unique combination of distributed computation, low-latency communication, and high-performance actuators provides an ideal FHT platform.

- Two Networks

- Gigabit Ethernet for non deterministic applications

- Shared Common Random Access Memory Network (SCRAMNet) for deterministic applications

- Low latency (sub micro second)

- Reflective memory (low host overhead)

- Supports synchronization through network interrupts

MTS Digital Control and Data Acquisition System

- Integrated 48-channel data acquisition for conventional transducers (LVDTs, strain gages, accelerometers, etc)

- Controls the three high-performance servo-hydraulic actuators

- Accepts commands from, and writes acquired data to SCRAMNet

- Synchronizes hosts on SCRAMNet by generating a network interrupt every millisecond

MTS Channels

- Six channels for each actuator (Command, Displacement, Force, Delta P, Valve Command, Valve Position)

- 26 Channels with Digital Universal Conditioners (DUCs) used for strain, voltage inputs

- 10 LVDT inputs (4 x 0.5 in, 4 x 1.0 in, 2 x 3.0 in)

- Three accelerometer channels (± 8g)

- Three linear encoder channels

- All data is digitally down sampled and anti-alias filtered

- Sampling rates up 1024 Hz with 16-bit resolution

MTS Transducers

- LVDTs

- Accelerometers

- Linear Encoders

National Instruments

PXI Equipment

- GHz Embedded Controller running LabVIEW Real-Time or WinXP

- SCRAMNet Interface Card

- Million Gate, 40 MHz Field Programmable Gate Array Card with 16-bit Analog I/O and Digital I/O

- 300K Sample/Sec. Multifunction I/O Card

- 40 unconditioned analog I/O channels, 112 digital I/O channels

SCXI Equipment

- Two Eight-Channel AC LVDT Conditioners

- Two Eight-Channel Universal Strain Conditioners with Programmable Excitation, Gain, and Filters

- Currently configured for 32 channels of conditioned analog input, can be expanded to 96+ channels if necessary

NI PXI System Special Features

- Flexible, modular instrument and signal conditioning architecture

- Real-time operating system for deterministic program execution (LabVIEW RT)

- FPGA "Hardware-In-The-Loop" card translates LabVIEW software into hardware for parallelized operation at 40 MHz.

NI PXI / SCXI Applications

- Hybrid Data Acquisition System

- Records data from variety of sources:

- MTS controller channels

- Numerical model real time data recorder channels

- Onboard data acquisition channels

- Anything else connected to SCRAMNet

- Synchronizes all data with MTS-generated SCRAMNet interrupt

- Capable of capturing over 500 channels at 1024 Hz.

- Supplementary Control System

- Route SCRAMNet memory values to analog and digital outputs

- FPGA card for special control needs

- Desktop Hybrid system development platform

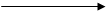

Video and Image Network

Robotic PTZ Video Cameras

- Two fixed cameras at north and south ends of lab

- Two wireless cameras for experiment-specific viewing

- Pan, Tilt, Zoom controlled from telepresence portal (http://neestp.colorado.edu)

- Video streams can be routed to Data Turbine server and viewed with the Realtime Data Viewer (RDV)

- Up to 20 frames/second at 640x480 pixels

Robotic Still Image Cameras

- Three Olympus C750 4.0 Megapixel cameras on robotic pan/tilt bases

- Controlled via LabVIEW GUI or web interface

- Captured images fed into Data Turbine for viewing with RDV

- Used for remotely viewing fine detail at low frame rates (10 seconds/frame)

VIC2D Image Correlation System

- Uses image correlation algorithms to provide full-field non-contact displacement and strain data for planar specimens

- Up to 30 frames/second at 1024x768 pixels

- Strain and displacement resolution determined by distance from specimen and lens configuration, down to 1/20 pixel

- Supports "virtual" strain gages and extensometers

- Captured image data is synchronized with analog or digital input signals

- Acquired data is currently not available for realtime viewing